Finding Prospects: U.S. Import Reliance Minerals

In response to the mining project development flowchart that we recently posted we have received many excellent comments. A few of these comments indicated that developing a more complex flowchart may be in order for the future. In the mean time, we have decided to expand upon some of these comments with additional articles and ideas as they open up new topics for consideration. One of these comments suggested that the first step on the chart, listed before picking a commodity and finding prospects, would be commodity and market research. In the spirit of further flushing out this proposed step on the chart we have done some of our own market research and are sharing the results with you. Finding prospects can be a daunting task, but we hope this article will give you some ideas.

19 Minerals with 100% U.S. Net Import Reliance

A logical first step of any market research program is to identify areas of the market that are under served and present opportunities to fill gaps in the supply chain. When finding prospects, consider starting your research by selecting a few of these 19 minerals. Many of these mineral resources are available to be developed in the United States, but are currently 100% imported according to the latest 2014 data. This data was compiled from the 2015 Mineral Commodity Summaries Report published by the US Geological Society. You can download the entire report here.

Arsenic

This toxic metal is used to produce gallium-arsenide (GaAs), indium-arsenide, and indium-gallium-aresnide semiconductors. New application of GaAs has increased in demand over the last several years and is now a $6.25 billion dollar industry. Arsenic has not been produced domestically since 1985.

Chances of finding prospects for arsenic: High, although mining and permitting are difficult due to its toxic nature.

Major import sources (2010-13): Morocco, China, Belgium

Asbestos

Due to health and liability issues, the demand for asbestos in the U.S. has declined and it hasn’t been mined in the U.S. since 2002. The U.S. imported 400 tons of asbestos through July of 2014. The chloralkali industry accounted for an estimated 88% of consumption in the U.S.

Chances of finding prospects for asbestos: High, but not recommended due to falling demand and liability issues.

Major import sources (2010-13): Brazil, Canada

Bauxite

U.S. consumption of this important alumina base was 9.6 million tons in 2014. This accounts for $269 million dollars of bauxite, more than 95% of which was converted to alumina. The remaining 5% was used in non-metallurgical products.

Chances of finding prospects for bauxite: Low. U.S. resources are inadequate to meet long-term demand while there are inexhaustible foreign reserves available.

Major import sources (2010-13): Jamaica, Brazil, Guinea, Australia

Cesium

Although the United States contains known deposits of pollucite, a principal cesium mineral, the majority of imports come from the largest known North American deposit in Manitoba, Canada. Cesium is primarily used in the form of chemical compounds for use in the oil and gas industry, but it is also used in a wide range of technical applications. Import data for this unique mineral have not been available since the late 1980’s.

Chances of finding prospects for cesium: High. Known deposits for cesium containing pegmatites occur in Alaska, Maine, and South Dakota.

Major import sources (2010-13): Canada

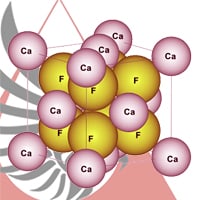

Fluorspar

The United States imported 578,000 tons of fluorspar in 2014. This important mineral is a key ingredient for the production of hydrofluoric acid. It is also the primary feedstock for the production of virtually all fluorine-bearing chemicals. It is also used in iron and steel casting, aluminum production, glass making, welding rod coatings, enamels, and cement production. At $310-450 a ton, fluorspar imports in 2014 amounted to an estimated $200 million dollars.

Chances of finding prospects for fluorspar: High. Quality deposits of fluorspar are known to occur throughout the U.S., with the largest historically producing deposits located in Southern Illinois.

Major import sources (2010-13): Mexico, China, South Africa, Mongolia

Graphite (Natural)

Graphite isn’t just used for pencils, this important flake and amorphous mineral is used in brake linings, foundry operations, lubricants, refractory applications, and steelmaking. In 2014, approximately 90 U.S. firms consumed $57.5 million dollars worth of graphite. Total natural graphite imports were 62,400 tons. Worldwide and domestic graphite demand is expected to increase over the next decade as it is an important component of electric car batteries.

Chances of finding prospects for graphite: Medium. Graphite deposits occur throughout the mainland U.S. and Alaska. Only a few deposits are known to contain quality natural flake graphite.

Major import sources (2010-13):China, Mexico, Canada, Brazil

Indium

Somewhere between $69.5 million and $104 million dollars worth of indium metal was imported into the United States. This conductive metal is used for flat panel LCD displays, alloys and solders, compounds, electrical components and semiconductors, and research. This key technology metal fetched an average 2014 price of $695 per kilogram.

Chances of finding prospects for indium: Low-Medium. Indium is found primarily in the ore mineral sphalerite. While domestic deposits of host ore minerals are well known, economic recovery is difficult.

Major import sources (2010-13):China, Canada, Belgium, Japan

Iodine

Although there is some domestic production of iodine from brines, the majority of reported consumption is fed by imports. Iodine prices have declined in 2014 owing to a surplus on the market. The average cost of iodine imports in 2014 was estimated to be $39.00 per kilogram. According to the USGS, iodine is used by downstream manufacturers to produce many intermediate iodine compounds, making it difficult to establish an accurate end-use pattern.

Chances of finding prospects for iodine: Low. Iodine produced through brines is generally thought to be economically superior to other methods.

Major import sources (2010-13): Chile, Japan

Manganese

Manganese ore containing 20% or more manganese has not been produced in the United States since 1970. This ore is consumed primarily in industries related to steel production, although it is also used in smaller quantities to produce dry cell batteries, in plant fertilizers, as a brick colorant, and in animal feed. The value of this domestic consumption in 2014 was about $1.2 billion dollars.

Chances of finding prospects for manganese: High. There are known and likely undiscovered deposits of manganese in the United States.

Major import sources (2010-13): South Africa, Gabon, Australia, Georgia

Mica (Natural Sheet)

While domestic scrap and flake mica production in the U.S. was estimated to be 49,500 tons valued at $6 million dollars, only a very minor amount of sheet mica was produced with the remainder imported to meet demand. Imports of natural sheet mice amounted to 2,290 tons in 2014 with 94% of these imports coming from India.

Chances of finding prospects for natural sheet mica: Low. Many mica mines are operating through the United States already with only very minor sheet mica production.

Major import sources (2010-13): India, China

Niobium

Significant domestic production of this important steel and aerospace mineral have not been reported since 1959. Many domestic resources are of a low grade and are not commercially recoverable. In 2014 the estimated value of niobium imports was $500 million with 79% being used in steel and 21% in superalloys.

Chances of finding prospects for niobium: Low. While domestic resources are known, they are generally not known to be commercially recoverable.

Major import sources (2010-13): Brazil, Canada

Quartz Crystal (Industrial)

Quartz crystal is the best material for frequency-controlled oscillators and frequency filters in electronics. Cultured quartz crystal production does exist in the United States, but no statistics are available according to the USGS. Virtually all quartz crystal used for electronics domestically is cultured rather than natural crystal. The price for these cultured quartz crystals was estimated to average $200 per kilogram in 2014. When these crystals are processed by sawing and grinding, they fetched an estimated $400 per kilogram in 2014.

Chances of finding prospects for quartz crystals: Low. Cultured quartz crystal is generally more economically suitable for most applications.

Major import sources (2010-13): China, Japan, Romania, United Kingdom

Rubidium

This important bio-medical research, electronics, specialty glass, and pyrotechnics product is not a major constituent of any mineral. It is not actively mined in the United States, however, occurrences are known throughout the country. It is produced in small quantities as a byproduct of cesium, lithium, and strontium mining. Annual rubidium consumption domestically is estimated to be approximately 2,000 kg and no market price data is published because the metal is not traded in commercial quantities. One company in 2014 was offering 1-gram ampoules of 99.75% grade rubidium for $80.30.

Chances of finding prospects for rubidium: High. Occurrences of rubidium in zoned pegmatites occur in several areas of the United States.

Major import sources (2010-13): Canada

Scandium

Although the ability to produce scandium domestically is available through mining and from processing mine tailings, the principal source of the metal and its compounds in 2014 was China. This metal is used to produce solid oxide fuel cells, aluminum-scandium alloys, ceramics, lasers, lighting, and radioactive isotopes. While accurate domestic import data is not available, it is known that global supply and consumption of scandium is estimated to be about 10 to 15 tons per year.

Chances of finding prospects for scandium: Medium. Scandium has been recovered from mine tailings, particularly from tantalum and uranium ore tailings. Geologist believe there are still significant deposits of scandium-bearing minerals waiting to be discovered.

Major import sources (2010-13): China

Strontium

Known deposits of strontium minerals occur widely throughout the United States, although they have not been mined since 1959. A few domestic companies produce small quantities of downstream strontium chemicals from imported strontium carbonate. While strontium can be used for a variety of end-uses, it is thought that virtually all consumption of the mineral in the United States since 2006 was in drilling fluids for oil and gas wells. In 2014, 33,000 tons of strontium was consumed domestically, with the majority coming from Mexico at an average price of $50 per ton.

Chances of finding prospects for strontium: Medium. Strontium was mined in California and Texas during World War II.

Major import sources (2010-13): Mexico, Germany, China

Tantalum

It is estimated that most domestic tantalum resources are of low grade and not currently commercially recoverable although it was successfully mined prior to 1959. Tantalum is primarily consumed mostly in the form of alloys, compounds, fabricated forms, ingots, and metal powders. Capacitors produced with tantalum account for more than 60% of use internationally. The value of domestic imports of tantalum in 2014 exceeded $250 million dollars.

Chances of finding prospects for tantalum: Low. Tantalum deposits in the United States are known to be low grade and generally not commercially recoverable.

Major import sources (2010-13): China, Germany, Kazakhstan, Russia

Thallium

Thallium has not been recovered in the United States since 1981. The price of this mineral has increased for the fifth consecutive year as global supplies continue to be constrained. In 2014 the estimated domestic consumption of this metal and its compounds was valued at $972,000. It is used for medical purposes in a radioactive form, and it also used for a variety of other optical and high-tech uses. Due to price increases, domestic use of thallium has declined as cheaper alternatives are found.

Thallium has not been recovered in the United States since 1981. The price of this mineral has increased for the fifth consecutive year as global supplies continue to be constrained. In 2014 the estimated domestic consumption of this metal and its compounds was valued at $972,000. It is used for medical purposes in a radioactive form, and it also used for a variety of other optical and high-tech uses. Due to price increases, domestic use of thallium has declined as cheaper alternatives are found.

Chances of finding prospects for thallium: Medium. Thallium is contained in several ores mined or processed in the United States although it has not been recovered domestically since 1981. It can be recovered from flue dusts and residues collected in the smelting of copper, lead, and zinc ores.

Major import sources (2010-13): Germany, Russia

Thorium

The world’s primary source of thorium is the rare-earth mineral monazite. This rare-earth is generally recovered as a byproduct of processing heavy-mineral sands for titanium and zirconium. Although less than 10 companies process or fabricate various forms of thorium for use in catalysts, high-temperature ceramics, and welding electrodes, it’s use has decreased due to it’s naturally occurring radioactivity. The demand for thorium may change in the future as it has potential as a uranium alternative for thorium-fueled nuclear power.

Chances of finding prospects for thorium: High. There are several large deposits of thorium known in the United States. These may become economical if it is further used as a uranium alternative in nuclear power plants.

Major import sources (2010-13): India, France

Vanadium

In 2013, domestic production of vanadium as a co product of uraniferous sandstone mining on the Colorado Plateau was suspended. Imports for this important metallurgical alloying agent were 10,800 tons in 2014 at an average price of $5.80 per pound. It is known that domestic resources and secondary recovery, if developed, could be adequate to supply a large portion of the annual $138 million dollar U.S. demand.

Chances of finding prospects for vanadium: High. Vanadium production occurred domestically up until 2013 and could be restarted or new mines could be developed.

Major import sources (2010-13): Czech Rep., Canada, Rep. of Korea, Austria

Finding prospects can be a complicated process, but we hope this article gave you some ideas.

Not all of the minerals, metals, and commodities on this list are suitable candidates for you to consider while finding prospects, but some of them may have potential. While arsenic and asbestos may not be domestically produced, they do not currently make attractive targets for finding prospects. The large market and deposit availability of several of these other commodities such as fluorspar, manganese, and vanadium, may be worth considering while you continue on with your prospect finding research. We hope you have enjoyed this article on finding prospects in 2015, feel free to share it using the links below.

Please note that our estimates on chances of finding prospects for these commodities are based on our best guesses and may not be accurate.